GrowSave delivered their April Workshop on ‘Practicalities of Dehumidification’ at the University of Lincoln. The event featured talks from industry experts Van Dijk Heating and DryGair as well as a guided tour of the Lincoln Institute for Agri-Food Technologies (LIAT).

Presentations

The talks started with Ton van Dijk from Van Dijk Heating speaking about their active ventilation systems (AVS) and their operational ethos.

He outlined that within semi-closed greenhouses, the ventilation rate is generally aimed for 80m3/m2/hr to keep humidity under control. AVS allows for this to be reduced to 5-25m3/m2/hr, dependent on additional factors.

Ton mentioned an AVS tool, developed by Van Dijk, which allows the user to input information and receive a climate profile and suggested timings for humidity control.

The most efficient solution is a combination of AVS with heat pump, although this solution may not necessarily be the cheapest. A heat exchanger provides approximately 50% saving, and the heat pump reduces input by another 10%; but the electrification of the system presents changes and increased energy costs.

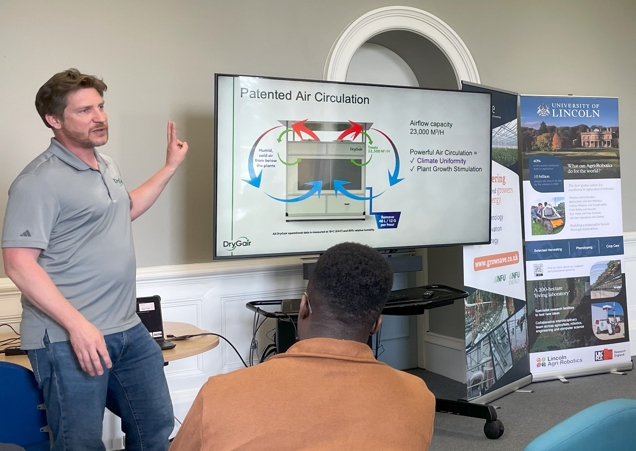

The next speaker was Justin Van Der Putten from DryGair, a company that is currently exploring ways to further reduce emissions through the use of different refrigerants.

DryGair’s presentation focused on a specific application: reducing humidity overnight to avoid morning dew-point condensation with the sunrise. Their research into dehumidification is extensive and involved several case studies across various crops, including vegetables, flowers, herbs, and cannabis.

Justin also spoke on their units designed for specific purposes, e.g., a taller model to fit between trays/rails, which increase the suitability of DryGair’s products across numerous glasshouse designs.

Amir Badiee gave a presentation on Project GASTRO’s research into the effects of proprietary NIR reflective glass, both to keep heat in as needed and reduce solar gain, as 45-50% of the heat input to a glasshouse is largely lost through the glass via heat emission.

The project aims to observe the outcome of comparing the proprietary NIR reflective glass against standard glass in a newly designed glasshouse and determine whether the process, yield, and quality of the crop are desirable.

Simon Pearson spoke on the advancement of robotics and artificial intelligence technology at the University of Lincoln, exploring novel ways of monitoring and harvesting a variety of crops.

The featured uses of robotics trialled by the University of Lincoln were crop monitoring for high-speed reviews of crop growth and quality, automatic selection and harvesting of mushrooms, and harvesting support led by self-guided robots capable of understanding human signals.

Site Tour

CambridgeHOK led a guided tour of the glasshouse construction for Project GASTRO, giving attendees the opportunity to ask about the construction process and the differences between a research-focused glasshouse and a commercial glasshouse.

The exterior of the glasshouse had been finished which allowed attendees to notice the difference between the proprietary NIR reflective glass and the standard glass, however there were still several weeks of work to complete.

Simon Pearson continued the tour around LIAT’s research facilities, stopping at the Barclays Eagles Lab where attendees were introduced to the respective experts on fertilisers and robotic learning. There were stops at the labs where the robots were being developed and stored, and introductions were made to the PhD students who were advancing each technology.

Partners / Associated

Lincoln Institute for Agri-Food Technology

Interdisciplinary Research & Innovation – to improve productivity, efficiency, resilience and sustainability across the agri-food sector. Specialising in robotics and AI technology from fundamental research to industry collaborations and commercial spin-outs supported by Barclays Eagle Labs.

SUSTAIN AI Centre for Doctoral Training Programme

Industry-focused PhD programme applying artificial intelligence technologies to support sustainable agricultural and food production. We are currently seeking collaborative partnerships so please contact [email protected] if you would like more information.

GASTRO is a strategic initiative poised to drive the UK’s CEA sector towards greater sustainability and productivity, delivering significant economic and environmental benefits regionally and nationally. GASTRO’s aims include:

1.Integrating and testing highly novel NIR glass coatings (spectral cooling) within UoL’s geothermal facility.

2.Demonstrating the full potential of geothermal and spectrally cooled technology on strawberry crops.

3.Development of a novel geothermal glasshouse design service to support technology roll out.